Hot Mounting Resin

Hot Mounting Resin

Couldn't load pickup availability

The purpose of mounting is to protect the integrity of the edges of the material and facilitate the clamping of the sample.Mounting can be divided into two types: Hot Mounting and Cold Mounting.

Hot Mounting Resin

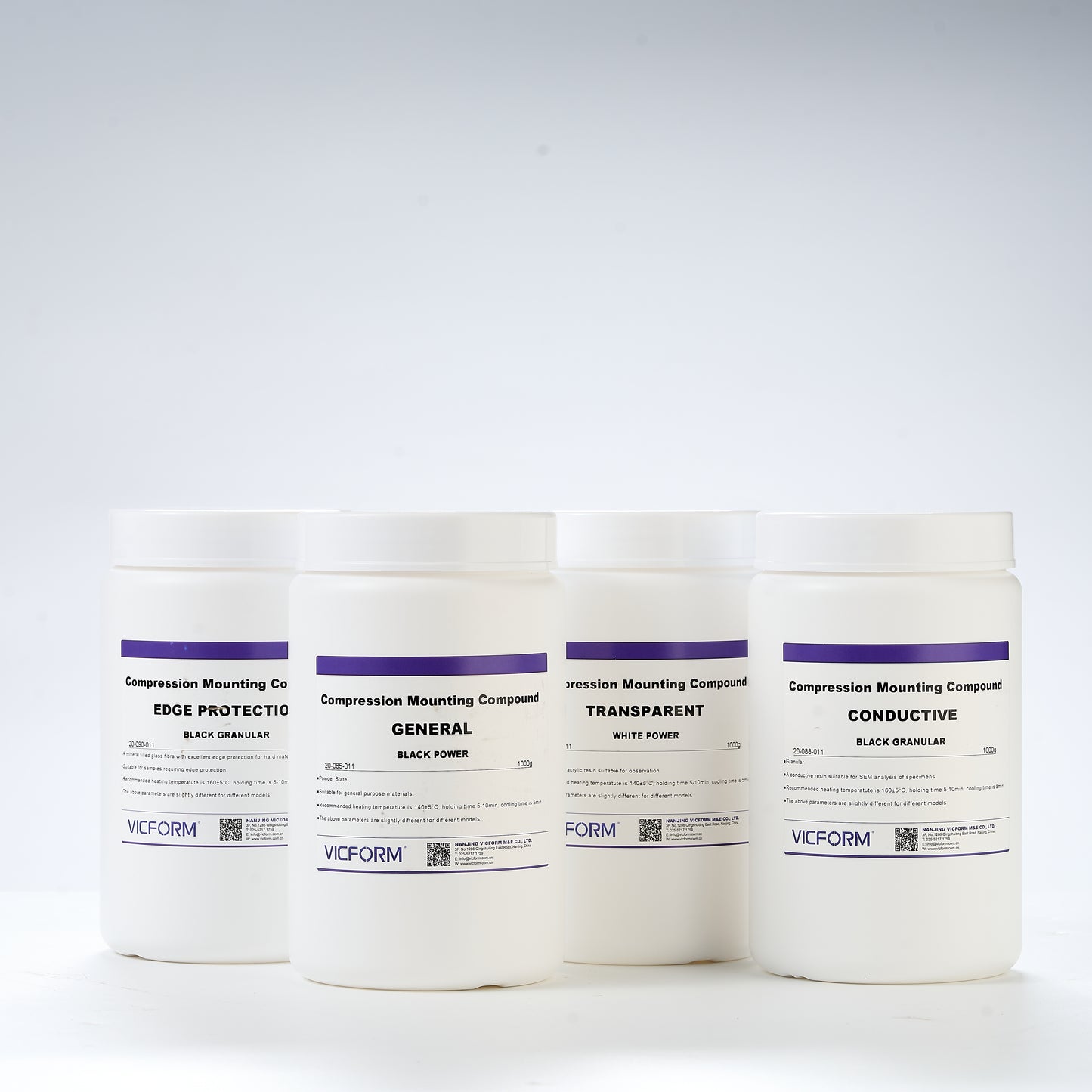

1)Complete Product Line

There are many types of mounting powders, and we have developed hot mounting materials with different characteristics for different scenarios. For example: ordinary mounting materials without special requirements, edge protection mounting materials that require edge protection, high hardness mounting materials for high hardness materials, conductive mounting materials for scanning electron microscopy requirements, and transparent mounting materials that are easy to observe, etc.

2) Safety and Environmental Protection

Free from harmful substances, safe and environmentally friendly, with no adverse effects on the human body during storage and use.

3) Excellent Performance

During the mounting process, it has good fluidity and adhesion to the sample, which in turn provides excellent protection for the sample; The mounted sample has high density and good resistance to chemical corrosion.

Specifications: 1kg/ bucket, 4kg /bucket

| Material | Application | Colour | Hardness (Shore D) |

Edge Protection |

| Phenolic resin 20-085-011 20-085-014 |

general mounting | Black | 75~85 | 🌟🌟🌟 |

| Phenolic resin 20-080-011 20-080-014 |

general mounting | Red | 70~80 | 🌟🌟🌟 |

| Phenolic resin 20-080-021 20-080-024 |

general mounting | Green | 70~80 | 🌟🌟🌟 |

| Edge-preserving resin 20-090-011 20-090-014 |

fiberglass contained can protect the edge | Brown | 85~90 | 🌟🌟🌟🌟🌟 |

| High hardness resin 20-092-011 20-092-014 |

Used for extrem hard materials to avoid chamfering during grinding | Black | 85~90 | 🌟🌟🌟🌟🌟 |

| Transparent resin 20-087-011 20-087-014 |

For samples that need to be observed | Black | 86~87 | 🌟🌟🌟🌟 |