Cut-off Wheel with Inner Diameter 32mm (10 pcs/ package)

Cut-off Wheel with Inner Diameter 32mm (10 pcs/ package)

Couldn't load pickup availability

The main purpose of cutting is to extract the analysis area and obtain the size of the required area.The sample properties should be retained to avoid thermal damage and deformation during cutting and the cutting surface should be flat.

*Complete Product Line

There are a wide variety of cutting pieces that can meet the needs of different materials. We will choose cutting blades with different abrasives and adhesives based on different materials and hardness. For materials exceeding HV700, diamond or CBN will be chosen, while for cutting most other materials, silicon carbide or alumina abrasive will generally be chosen, and the bonding method is usually resin。

*Stable Performance

The cutting blade strictly controls the particle size, purity, and adhesive of the abrasive to ensure consistent preparation process and stable performance of each cutting blade.

*Wide Applications

Whether you are in the Electronics, Automotive, Semiconductor, Integrated Circuit, Medical, Wind power and other industries, there is always a cutting blade that can meet your needs.

This cut-off wheel provides excellent cutting results without burning the material and with minimal surface deformation.

Cutting discs are resin bonded, thickness is marked below the item number.

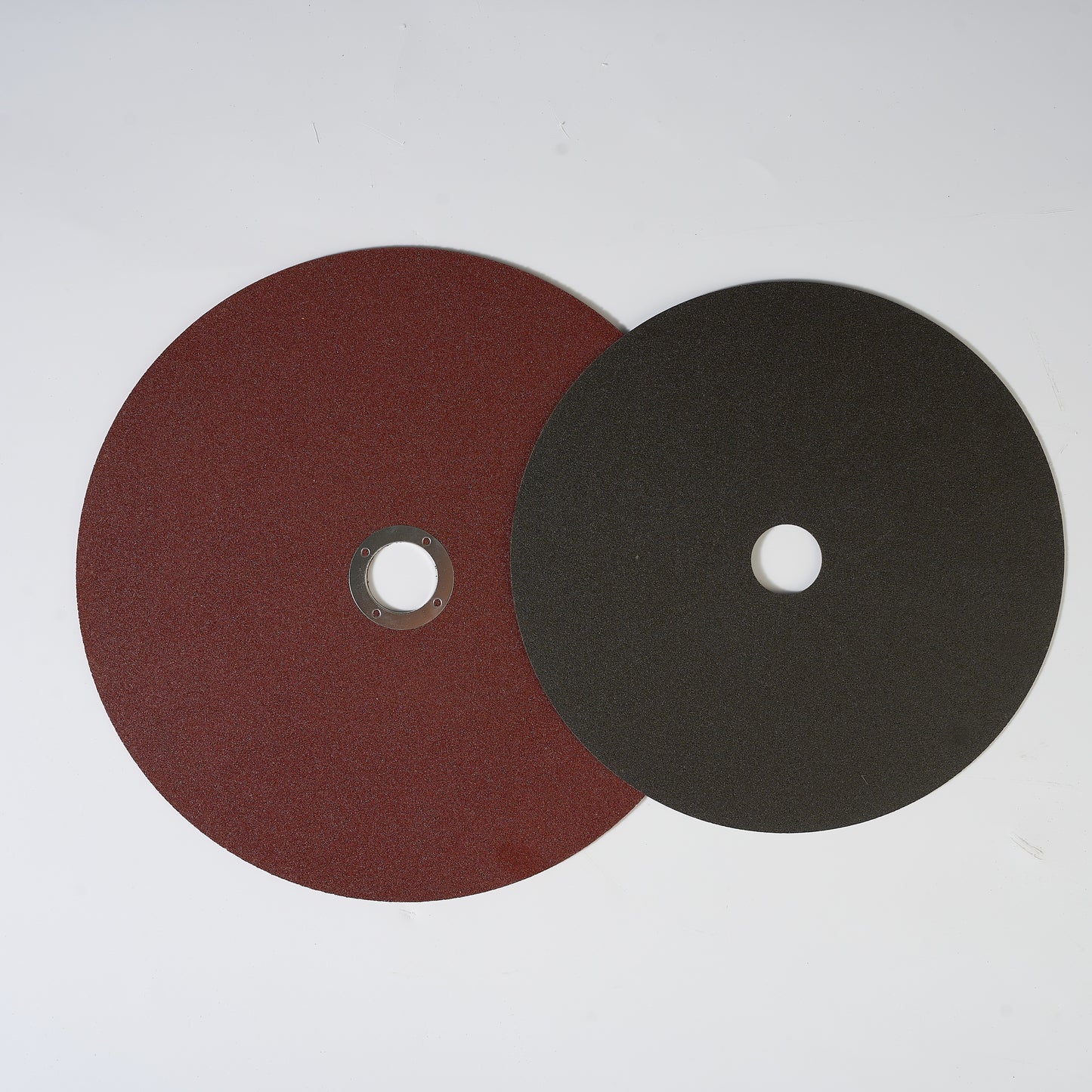

Silicon carbide abrasive=Blue

Black Aluminum Oxide Abrasive=Black

Brown-red aluminum oxide abrasive=Brown-red

| Recommended materials | 250mm | 300mm | 350mm | 400mm |

| Extremely hard black metal 550<HV<1000 |

10-060-060 (1.2mm) 11-060-060 (1.5mm) |

10-060-080 (2.0mm) 11-060-080 (2.0mm) |

10-060-090 (2.0mm) 11-060-090 (2.5mm) |

11-060-100 (2.8mm) |

| Hard black metal 450<HV<600 |

10-050-060 (1.2mm) 11-050-060 (1.5mm) |

10-050-080 (2.0mm) 11-050-080 (2.0mm) |

10-050-090 (2.0mm) 11-050-090 (2.5mm) |

11-050-100 (2.8mm) |

| Medium hard black metal 300<HV<500 |

10-040-060 (1.2mm) |

10-040-080 (2.0mm) 11-040-080 (2.0mm) |

10-040-090 (2.0mm) |

11-050-100 (2.8mm) |

| Softer black metal 50<HV<400 |

10-030-060 (1.2mm) 11-030-060 (1.5mm) |

10-030-080 (2.0mm) 11-030-080 (2.0mm) |

10-030-090 (2.0mm) 11-030-090 (2.5mm) |

11-030-100 (2.8mm) |

| Titanium alloy and other high-toughness metals, high-temperature alloys 70<HV<400 |

12-020-060 (1.2mm) |

12-020-070 (1.5mm) |

12-020-080 (2.0mm) |

|

| Softer non-ferrous metals such as aluminum and copper 30<HV<300 |

12-010-060 (1.2mm) |

12-010-070 (1.5mm) |

12-010-080 (2.0mm) |